We are a Polish manufacturer of dental implants. Thanks to an interdisciplinary approach and the rich experience of our Research Team, we have designed an implant system that meets the highest global standards.

Serial Implants

Custom Implants

Subperiosteal implants are made from titanium alloy (Ti6Al4V) using Selective Laser Melting (SLM) technology and are printed based on images obtained from computed tomography.

Implantology Training

Training in the implantation of subperiosteal and jaw implants is extremely important for professionals wishing to improve their skills and expand their knowledge. We offer you advanced individual and group training in your office or in the office of our surgeon.

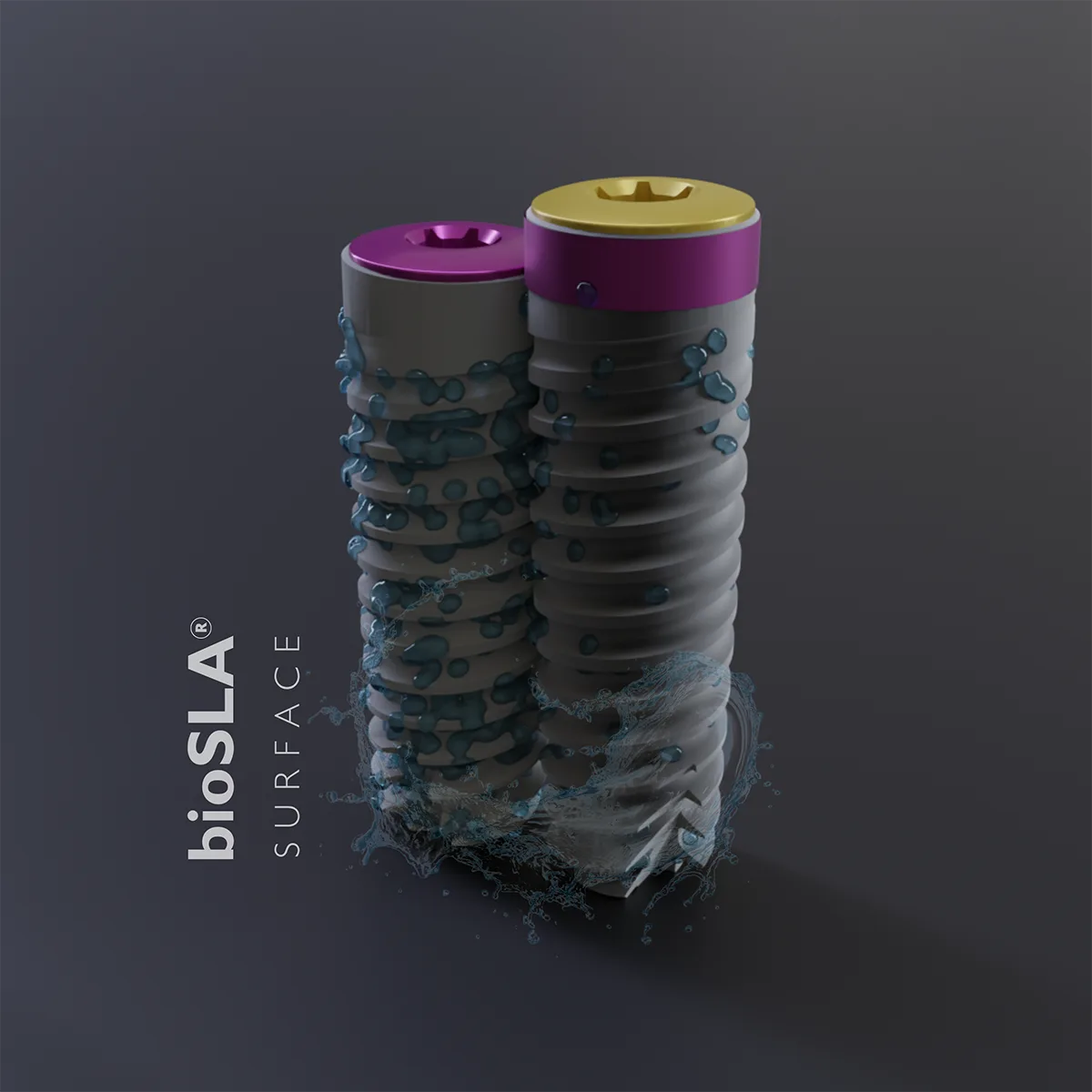

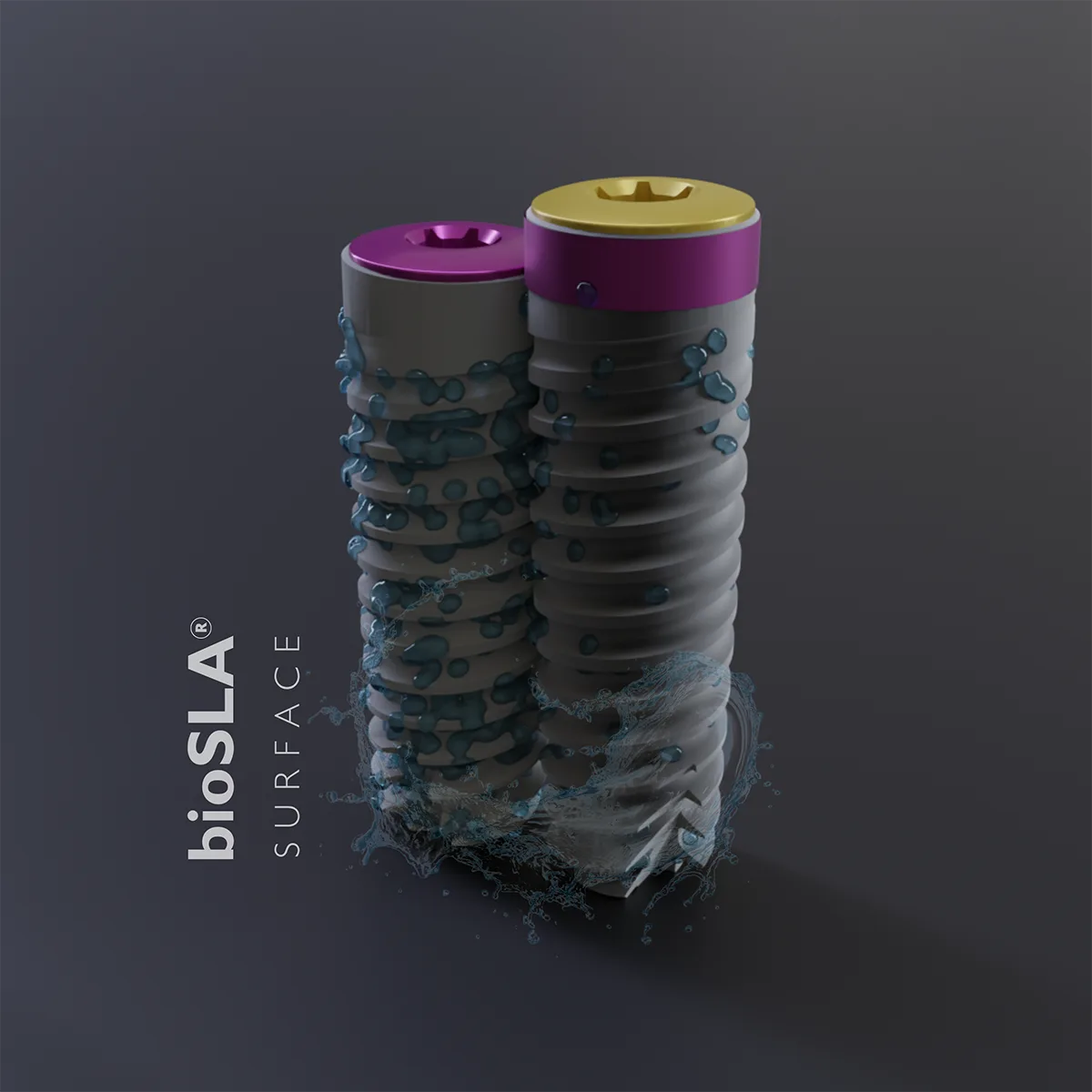

Serial implants

The Polish implant system is made from pure GRADE 4 titanium. The surface of the implants is sandblasted with titanium oxide and etched with dedicated acids, and is also free from aluminum oxide. We offer two lines of implants for sale: one with a sandblasted neck for supracrestal placement in the bone and another with a pink neck.

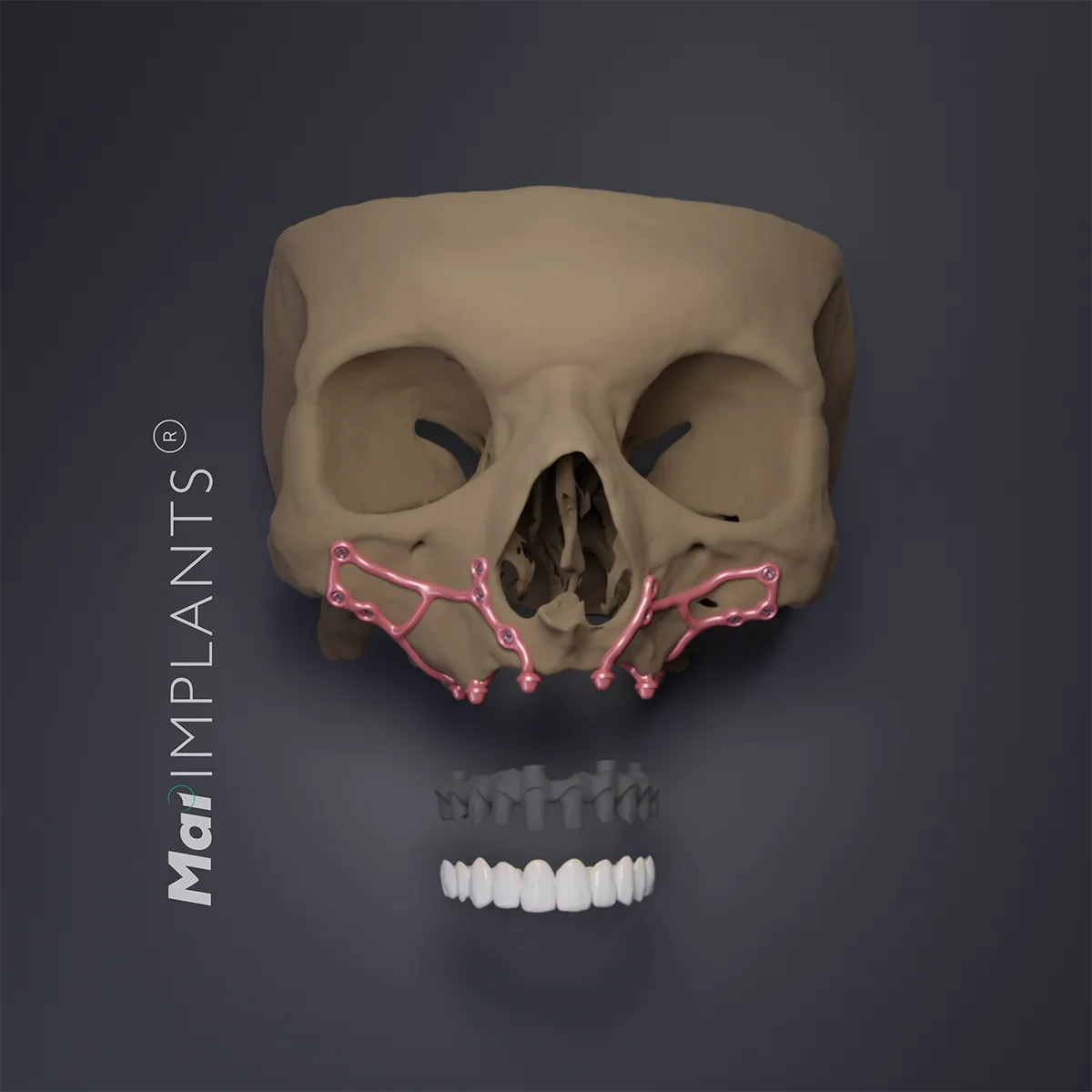

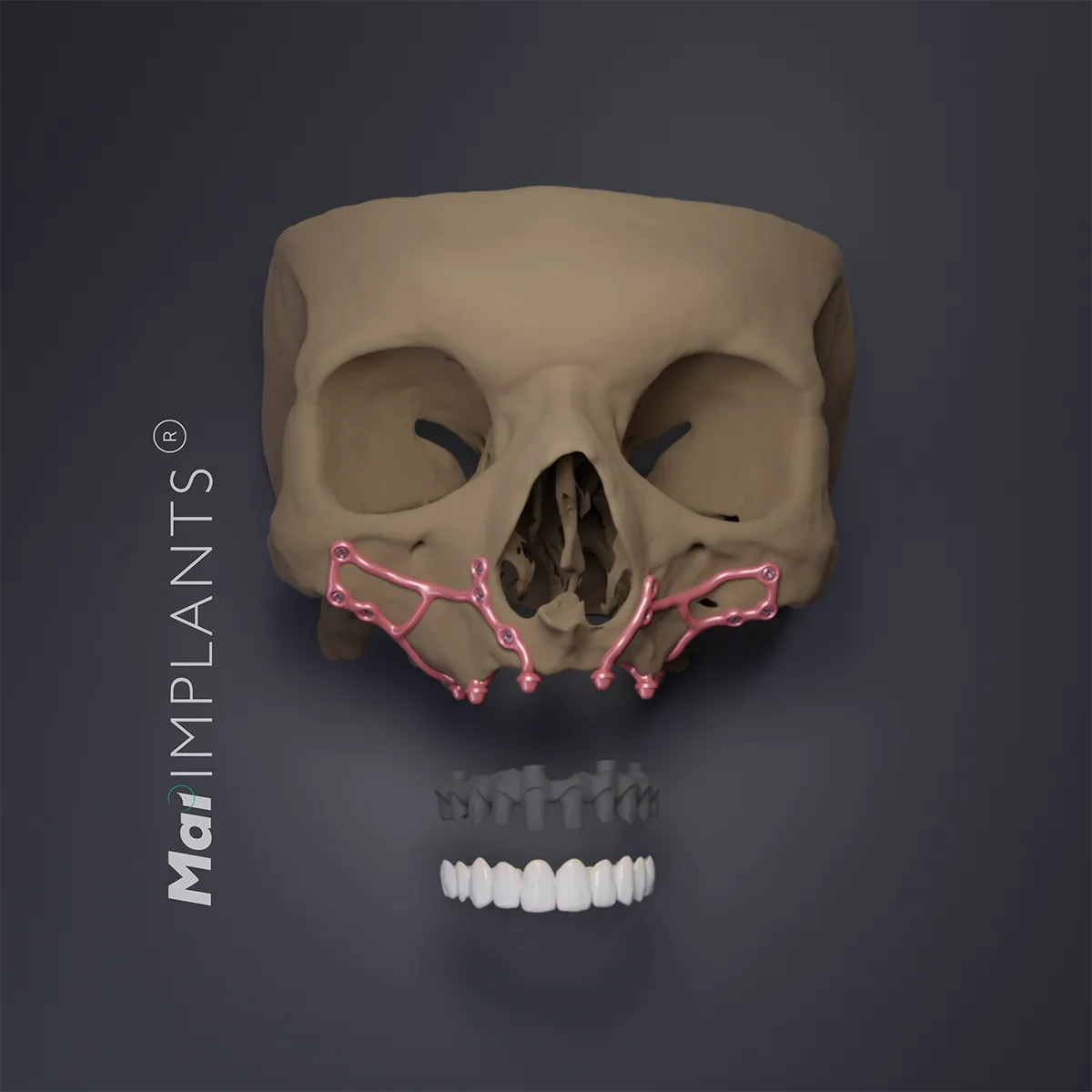

Custom implants

Our 15 years of experience with innovative digital technologies and 3D printing have become the basis for the production of individual subperiosteal implants.

Subperiosteal implants are made from titanium alloy (Ti6Al4V) using Selective Laser Melting (SLM) technology and are printed based on images obtained from computed tomography.

Implantology Training

Training in the implantation of subperiosteal and jaw implants is extremely important for professionals wishing to improve their skills and expand their knowledge. We offer you advanced individual and group training in your office or in the office of our surgeon.

A qualified team oversees the entire production process and is always ready to answer your doubts or questions.

Webdesign – Piotr Sierant