DMG MORI Ultrasonic 20 linear 5-Axis-Champion

Compact, precise machining center, ensuring process reliability with acceleration > 2 g and spindle rotational speed up to 60,000 rpm

Max. X-axis travel – 200 mm

Max. Y-axis travel – 220 mm

Max. Z-axis travel – 280 mm

Max. table load – 15 kg

Table diameter – 250 mm

TORNOS EVODECO 16/10

The highest class Swiss-type automatic lathe used for turning and milling micro-details.

Machines ensure the maintenance of strict tolerances, high repeatability at the highest global level.

Vision Engineering DRV-Z1

Vision Engineering DRV-Z1 is a completely new solution in manual optical inspection. Stereoscopic, digital 3D image is projected onto a concave mirror in real-time, with excellent depth of focus.

DRV-Z1 operates in full HD resolution and has a zoom range of 6 – 186x.

The perfectly reproduced depth of focus supports all operations that the user will perform on the component plate. The ergonomic arrangement of knobs for adjustment in the DRV-Z1 microscope, exceptionally easy operation, comfortable working position are just a few of the advantages of the device.

DMG MORI LASERTEC 12

The latest SLM machine from DMG MORI. It has a highly precise laser focal length of 35 µm. The use of additional filters, significantly improved gas flow, and a change in the system for removing dirty and supplying clean powder allows achieving perfect quality of manufactured elements. Thanks to the rePLUG system, it is possible to quickly and safely change the material. Like the Realizer SLM 100 and DMG MORI SLM 125, this machine has a working area of 125mm x 125mm, allowing the placement of about 140 points during one cycle.

3D Printer ProJet MJP 2500

The ProJet® MJP 2500 Series combines professional quality, affordable price, and compact size. The printer allows for precise printing of models in high quality with great durability and flexibility.

- The latest 3D printer ProJet® MJP 2500 Series.

- Precise and accurate 3D models of hard plastic or with an elastomer additive.

- The highest quality, accuracy, and smooth surface of 3D models are a huge advantage of all printers in the ProJet series.

- Maximum performance and functionality, automatic 3D printing process, state-of-the-art software, and modern device design are the advantages of 3D printers from 3D Systems.

- New materials with an elastomer additive allow for printing flexible models with a smooth surface without visible layers of applied material, and a clear material is also a novelty.

ARBURG ALLROUNDER 470E GOLDEN ELECTRIC

A modern injection molding machine for the production of plastic elements.

Innovative drive technology makes the injection molding machines with a clamping force range from 350 to 6500 kN reliable and economical. Reproducibility and part quality thanks to a backlash-free, directly acting screw puller.

Thanks to the use of a liquid-cooled servo-electric drive, the injection molding machine has a low emission level.

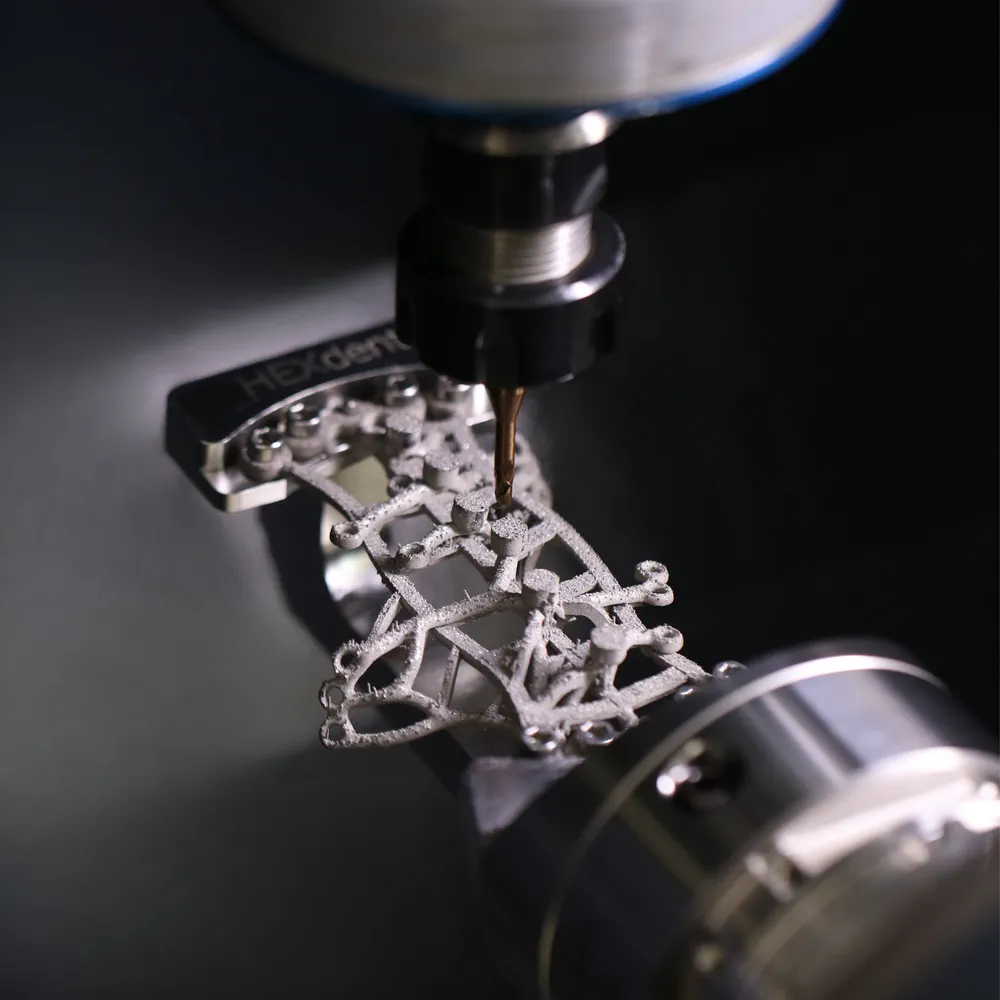

CORiTEC 350i PRO

A 5-axis dental milling machine created from scratch for machining materials such as zirconium and PMMA as well as hard metal alloys, CoCr, and Titanium.

The integrated wet processing system in the device also allows for grinding glass-ceramics. The fully automated tool magazine holds 20 tools necessary for machining the full range of materials.

DMG MORI SLM 125 i 100

DMG MORI REALIZER SLM 100

Industrial 3D printer. Uses Selective Laser Melting (SLM) 3D printing technology. SLM technology melts metal powders using a strong laser beam. After forming a layer of solid metal, the plate containing the 3D print is lowered, and powder is applied on top. Laser sintering is resumed for the new layer. Layer by layer, the object is printed in three dimensions until completion.

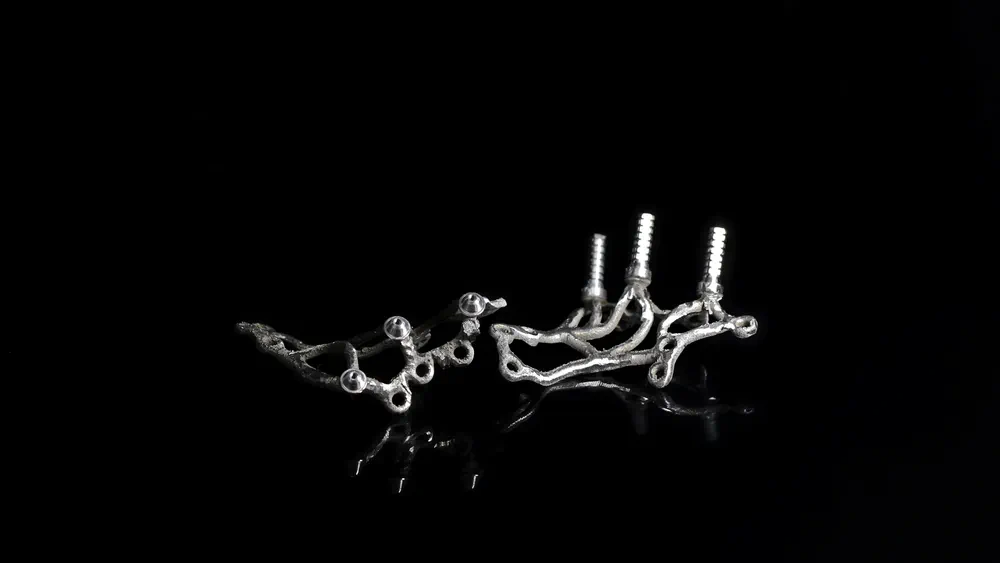

DMG MORI REALIZER SLM 125

A newer generation of the Realizer SLM machine. Allows for rapid printing of crown, bridge, and skeletal prosthesis structures from cobalt-chromium alloys while maintaining 100% passivity and tightness. It is the first SLM machine with an integrated powder sieving system.

A qualified team oversees the entire production process and is always ready to answer your doubts or questions.

Webdesign – Piotr Sierant